Corrugated Metal Sheets

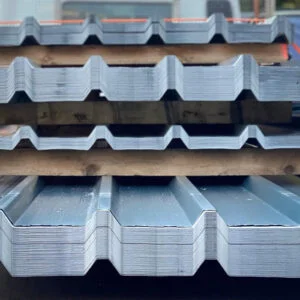

Corrugated metal sheets are sheets of metal that have been formed into a series of parallel ridges and grooves, creating a distinctive wavy or corrugated pattern. Here's what you should know about corrugated metal sheets:

Benefits: Box profile cladding offers several benefits, including:

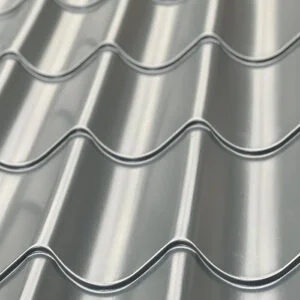

1.Appearance: Corrugated metal sheets have a characteristic wavy pattern formed by alternating ridges and grooves. This design provides strength and rigidity to the metal while also enhancing its visual appeal. Corrugated metal sheets are available in various metals, including steel, aluminium, and copper, and can be finished with different coatings or paints to achieve desired aesthetics.

2. Materials: Corrugated metal sheets are commonly made from steel, which is known for its strength and durability. Aluminium and other metals may also be used depending on the application. The choice of material depends on factors such as the desired strength, corrosion resistance, and budget.

3. Applications: Corrugated metal sheets are versatile and used in a wide range of applications, including roofing, siding, fencing, and structural support. They are commonly used in both residential and commercial construction projects due to their durability, weather resistance, and ease of installation.

>4. Roofing: Corrugated metal sheets are popular roofing materials for both residential and industrial buildings. They provide excellent protection against weather elements such as rain, snow, and wind while also offering good durability and longevity. Corrugated metal roofing is often chosen for its low maintenance requirements and cost-effectiveness compared to other roofing materials.

5. Siding: Corrugated metal sheets are also commonly used as siding materials for exterior walls. They offer a modern and industrial aesthetic and can be installed vertically or horizontally, depending on the desired look. Corrugated metal siding provides excellent durability and resistance to moisture, making it suitable for various climates.

6.Fencing: Corrugated metal sheets are used for fencing and enclosure applications due to their strength and security features. They can be installed as standalone panels or integrated into other fencing systems for added security and privacy.

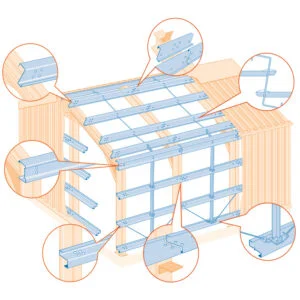

7.Installation: Corrugated metal sheets are installed by fastening them to the underlying structure using screws, nails, or other fasteners. Proper installation techniques are essential to ensure a weather-tight seal and optimal performance. Installation methods may vary depending on the specific application and building codes.

8. Maintenance: Corrugated metal sheets require minimal maintenance over their lifespan. Periodic inspections and cleaning to remove debris and prevent corrosion are recommended to ensure the longevity of the metal.

Overall, corrugated metal sheets are versatile, durable, and aesthetically pleasing materials used in various construction applications. They offer numerous benefits, including strength, weather resistance, and ease of installation, making them a popular choice for roofing, siding, fencing, and other building projects.